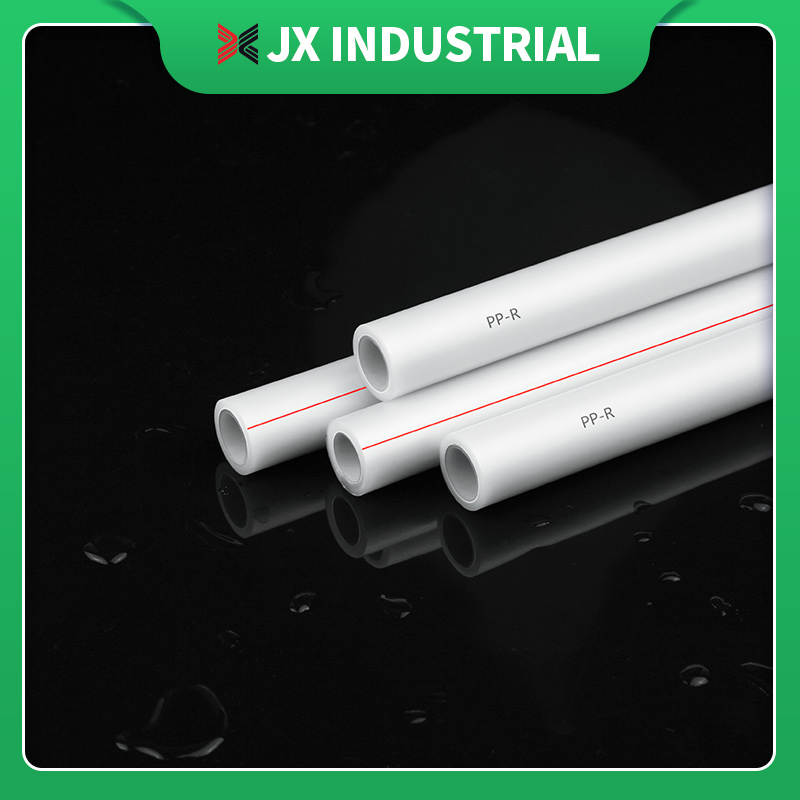

PPR (Polypropylene Random Copolymer) pipes and PVC (Polyvinyl Chloride) pipes are two commonly used materials in plumbing systems, each with its distinct characteristics and applications. Here are some key differences between PPR pipes and PVC pipes:

Material Composition: PPR pipes are made from a random polypropylene copolymer, which offers excellent resistance to high temperatures and chemical reactions. PVC pipes, on the other hand, are made from polyvinyl chloride, which provides good chemical resistance but is not as tolerant to high temperatures as PPR.

Temperature Resistance: PPR pipes are known for their impressive temperature resistance, capable of handling hot water up to 90 degrees Celsius and low temperatures as low as -25 degrees Celsius. While suitable for general plumbing applications, PVC pipes have lower temperature limits and may deform or become brittle when exposed to high heat.

Pressure Tolerance: PPR pipes have a higher pressure tolerance than PVC pipes. PPR pipes can handle water pressures up to 100 kilograms per square centimeter without bursting, making them suitable for applications that require higher pressure capabilities. PVC pipes have lower pressure ratings and may not be suitable for certain high-pressure plumbing systems.

Flexibility: PPR pipes are relatively more flexible than PVC pipes. This flexibility makes them easier to install in tight spaces and navigate around obstacles during plumbing installations. PVC pipes, while still somewhat flexible, are generally stiffer and may require additional fittings or connectors to navigate corners and bends.

Joining Method: PPR pipes are typically joined using a heat fusion technique, where the pipes are heated and fused, resulting in a seamless joint. PVC pipes, on the other hand, are commonly joined using solvent cement, which chemically bonds the pipes together. Heat fusion joints tend to be stronger and more reliable than solvent cement joints.

Chemical Resistance: While both PPR and PVC pipes offer good chemical resistance, PPR pipes are generally more resistant to a wider range of chemicals compared to PVC pipes. This makes PPR pipes suitable for applications in industries such as chemical processing, where exposure to various chemicals is common.

It's important to consider these differences when selecting the appropriate pipe material for a specific plumbing project. Factors such as temperature requirements, pressure demands, and chemical compatibility will help determine whether PPR or PVC pipes are better suited for the intended application. Consulting with a plumbing professional can provide further guidance in making the right choice for a specific plumbing system.